Your shopping cart is empty!

+1 (855) 251-0016 | sales@fuelcellstore.com

Categories

Quick Add To Cart

Latest Blog Posts

HYDRO-LAT 1400 AND HYDRO-LAT 2400 GAS DIFFUSION LAYERS WITH HYDROPHILIC MICROPOROUS LAYER

Background

Electrochemical technologies have been widely adopted for various commercial application.. Read More

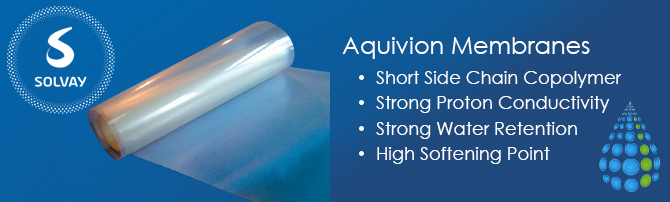

For PEM fuel cell and electrolyzer applications, a proton exchange membrane is sandwiched between an anode electrode and a cathode electrode. During electrochemical reaction, oxidation reaction at .. Read More